xiros guide rollers with FDA conformity: 60% weight saving compared to metallic solutions

Shery George | 21 January 2022

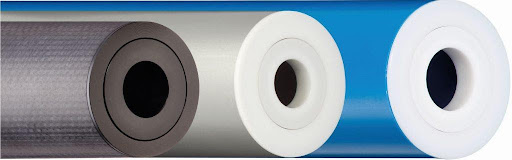

igus, develops maintenance-free and above all lubrication-free solution for transport and guide rollers, which are made of blue light weight PVC tube and FDA-compliant two fixed flange ball bearings made up of in-house material xirodur B180 and stainless steel balls under the brand name xiros.

These xiros guide rollers are particularly important for labelling, packaging and food applications due to possible contamination of food.

Plastic solution to save drive force-

The PVC tube weighs only about one third as much as comparable stainless steel tubes. This has a positive effect on the required drive force when the rollers are set in motion. Due to the fact that xiros polymer ball bearings are lubrication-free, the balls do not run against the resistance of the lubricant; unlike their metal counterparts. The advantage is that they can be set in motion much more easily than metal ball bearings due to the low friction.

A complete range of Xiros guide rollers-

Apart from PVC tube material, xiros® guide rollers are available in various tube materials like aluminium, stainless steel & carbon. With diameters from 20 to 100 mm and lengths of up to 1,500 mm. Special parts such as ready-to-install systems with shafts are also possible.

Advantages of Ready-to-install film guide rollers from Igus .

- As they are lubrication free, the torque required is much lower then metallic lubricated bearings solution.

- Special sand blasted rollers are also available to get better grip and avoid film from slipping.

- Special bearings with a projecting flange that prevents the film from jumping over can also be used.

- Lengths and diameters are also very flexible – we have a wide range of standard bearings to draw on.

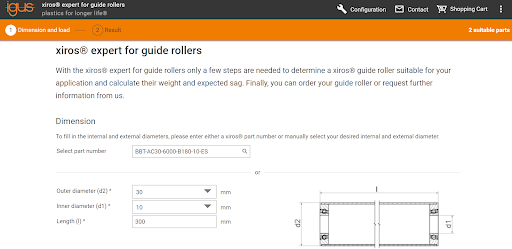

- Predictable life of rollers by expert calculation.

What is the service life of a guide roller?

Ultimately, the question remains: “How long will the roller last?”

Our calculation tools can determine the answer for your application. External influences, such as contamination and cleaning media, are taken into account during selection of components and materials used.