Where are our gantries used?

Shery George | 26 April 2022

igus® gantries are used in countless different applications and industries, from picking & placment of components to pipetting applications. The opportunities are endless when it comes to igus® gantries, whether an application requires a speed of upto 1 m/s, accuracy of +/-0.5 mm with loads up to 10 kgs, the solution will be found using the options igus® gantry provides.

Which gantry should be used and where?

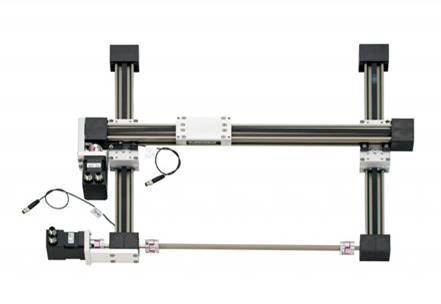

Flat gantries (also known as surface gantries) have XY axes and are suitable for predefined surfaces such as measuring, marking & glueing applications. The benefits of this type of gantry are that it features not only easy installation with its kit-form and modular design but also includes a proximity switch mounting which can be applied at any point across the length of the section.

Meanwhile, room or linear gantries are suitable for three-dimensional applications, and are the best choice for pick & place applications, pipetting, camera positioning or inspecting applications. The benefits of using this gantry are precise positioning and its ready-to-use kit design means the modules can be easily assembled and installed.

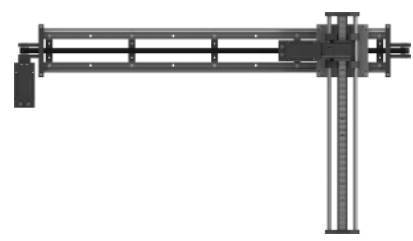

Last but not least, line gantries are suitable for tasks on vertical working planes such as for sorting systems in medical technologies or for picking and placing tasks in warehouses. Some benefits of these include speed and accuracy. With just two axes, this is ideal for fast and long-travel applications too.

All igus gantries are made up of at least 2 axes and are designed from top-down so that the solutions are best for the application.

Get in touch via the details below to find out more or click here to arrange a visit to the igus® factory.

Visit the website to find out more about the igus® gantries.