What are plain bearings and what advantages igus offers in Automotive industry?

Shery George | 12 November 2021

Plain bearings or commonly known as “bush”, bush bearing”, “bushing”, slide bearing” etc. are a much older technology when compared with ball bearings. Humans have been using plain bearings since year 3000BC. These are the simplest form of bearings without any rolling elements.

Some of the most desired features of a plain bearings are – it should have low friction, low wear, corrosion resistance, resistance to high temperatures etc. Considering these requirements, most used materials for plain bearings include bronze, brass, PTFE coated on metal etc.

Metallic bearings cannot always offer all the desired features. For an instance, a bronze bearing may have higher coefficients of friction and need to be used with lubrication. Plastic bearings could match most of the desired features of a plain bearing but plastics like nylon and Delrin may have limitations with the load carrying capacity, moisture absorption etc.

Thankfully, compounding of polymers overcomes these limitations. Compounding of polymers is the process of blending plastics with other additives & fibers to change the mechanical, thermal, electrical characteristics of the polymer to use as a bearing.

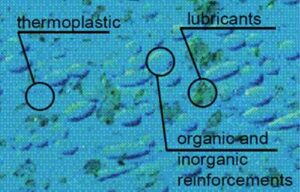

igus makes plain bearings from range of compounded polymers. These plain bearings are known as Iglidur polymer plain bearings. Iglidur bearings are made of extremely wear resistant tribo-polymers, solid lubricants and strengthening materials. igus has one of the biggest test lab in the industry where it develops hundreds of new iglidur materials every year and does more than 10000 tests every year for friction and wear values with different shaft materials. This real time testing creates a possibility to do a real time life calculation of bearing in automotive application & we can choose right material (from 150 special material compounds) for the right application which offers best price and higher life.

It is the biggest advantage that you can choose the correct iglidur material for your application using the online lifetime calculation tools expert for plain bearing and product finder for plain bearings,

Other Advantages of iglidur plain bearings are:

· Lubrication & Maintenance free for lifetime

· High load capacity for applications like suspensions

· Corrosion resistance and high media resistance for under boy applications

· High wear resistance to get higher life

· Lightweight to increase the fuel efficiency of vehicle

· Low coefficients of friction for application like pedals, levers etc.

· Electrical conductive material e-coating process for applications like hinges, seats etc.

· Predictable lifetime to give confidence to designer to test igus bushes in automotive applications

Author:

Mr. Nitin Prakash Vibhandik

Product Manager iglidur® Bearings

Tel.: +91 7760368383 Fax: +91 80 68127802

E-Mail: nprakash@igus.net