The three most common misconceptions about polymer plain bearings

Vishaka Upreti | 29 March 2021

Plastics have become an integral part of everyday life and have established themselves in all areas of industry over the past few decades. Most people are now aware that there is no such thing as “the plastic”, just as there is no such thing as “the metal”. In the search for ever lighter and more economical materials for all kinds of problems, plastics have long since become part of many solutions and help to expand the limits of what is possible. And yet, despite this flexibility and diversity in this world of plastics, there are blanket judgements and errors in practice. So today I want to shed light on some of them and examine them for their truthfulness.

Error number 1: Plastic plain bearings are simply too soft

The assertion is of course plausible. Plastics are “softer” than metal. All values such as compressive strength or surface hardness are significantly lower. And accordingly, plastic plain bearings are also “less durable” than metal.

The question, however, is what plain bearings actually have to withstand in their respective applications. Take a close look at the application parameters. How high is the load on the plain bearing really? Do you calculate the sheer load to be carried? Or the surface pressure on the bearing? It often turns out that the surface pressure, i.e. the load distributed over the bearing surface of the plain bearing, is not so enormous in the end. Even simple plastic plain bearings of 20 x 20mm size easily bear the weight of a small vehicle (30MPa surface pressure at a weight of approx. 1,200kg).

However, the most important point here is that these are plain bearings and purely load-bearing elements. Plain bearings should not simply carry loads statically, but dynamically – in other words, in motion. For this to be possible with metal plain bearings, these must be additionally lubricated. Dry-operating metal bearings in turn only work with polymer inlays. And these again have the same disadvantages as plain bearings made of polymer.

Error number 2: Polymer plain bearings have much more clearance and they rattle

You guessed it, a “yes, but” is valid here too. Yes, plain bearings made of polymer require a little more clearance than ball bearings, for example. But the comparison is misleading. Unlike ball or rolling bearings, plain bearings operate on the principle of sliding friction, whereas ball and rolling bearings operate with rolling friction. In order for the sliding movement to work, the components must be movable and supported with sufficient clearance. In addition, polymers expand under heat and moisture. However, this effect varies greatly with the type of polymer material. This means that polymers with lower thermal expansion and low moisture absorption can be used even with very little bearing clearance.

However, it is also true that rattling and the corresponding noise development during operation can be improved by using polymer plain bearings, as these – provided the right polymer is used – dampen vibrations better than metallic plain bearings. Here, too, it is important to take a close look at the situation in each application.

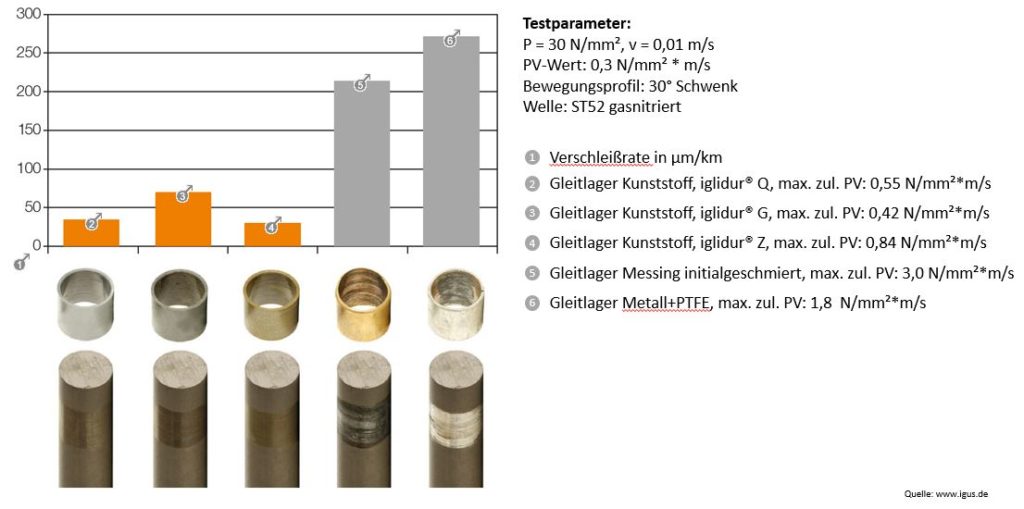

Error number 3: Polymer plain bearings do not last very long

Here, too, it all depends on the application. There are 2 types of metal plain bearings. Some only function as long as they are sufficiently lubricated with the right lubricant. The others work until the thin layer of sliding polymer is worn out. Polymer plain bearings usually consist exclusively of “wear-resistant material” and often run without additional lubrication. In addition to durability, maintenance and dependability are also an issue here. One of the most frequent causes for the failure of plain bearings is not the “natural” death but the premature failure due to lack of maintenance.

Conclusion: The right material is what counts

Just as there is not THE one metal for plain bearings, there is not THE one polymer for plain bearings. It is also true, however, that the choice can be very difficult. In the thicket of brands and trade and type designations, it is often difficult to find the right solution based only on data sheet and sales advice.