Seat height adjustment – noise free and lubrication free polymer plain bearing from igus

Shery George | 10 October 2022

Ached Backs and Strained necks are not a good combination for a long drive. A good comfortable driving position is derived from a lot of small adjustments to the seat support systems. More attention to these details has evolved into comfort and safety of the driver.

What is this Trend now in Seating Systems?

In the last decade, all that we had for seat adjustment was a lever or 2 to pull the seat front and back. The development of autonomous vehicles, as well as the demand for driving comfort has picked up drastically over the years. This is precisely where the seat height adjustment plays a decisive role. The right seat height provides the best view of the road and is an important contribution to the feeling of comfort and safety. This is also a reason for the increasingly common use of electric seat adjustments by means of actuators and compact motors. All these reasons result in an increasingly frequently used seat height adjustment.

Higher loads and requirements on the plain bearings within the seat height adjustment system

Even for a small number of seat adjustments, a high-quality bearing is needed, but the increased use of seat height adjustment brings a greater challenge to the plain bearings used. These now must withstand significantly more movements and loads than before. Economical counter partners (e.g. Rivets) and a low fine-cut portion ensure enormous load and wear requirements. Thin gliding layers on metal bearings can quickly become damaged or worn. The resulting noise is extremely undesirable because the seats must remain noiseless and adjustable without squeaking (BSR) for the entire life of the vehicle. Accordingly, the plain bearing material used in the seat height adjustment is responsible not only for minimizing wear and friction, but also for mitigating BSR and NVH noise within the seat structure.

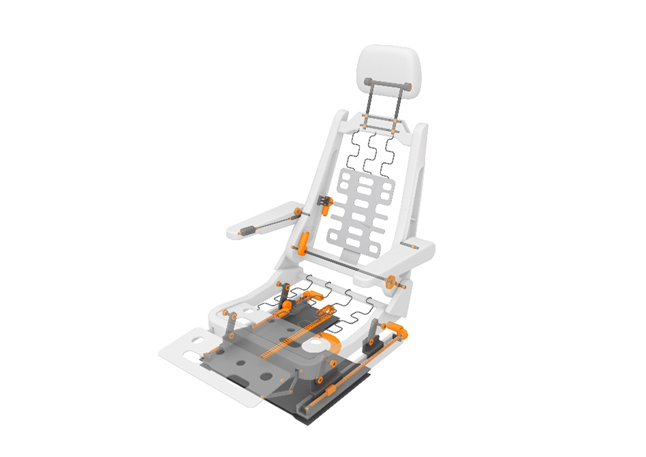

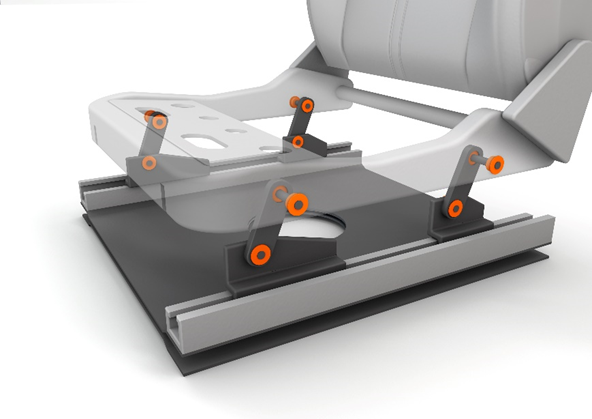

Where are the bearing points in the seat height adjustment?

The bearing points of the seat height adjustment are located between punched sheet metal hinges and sheet metal bindings or metal structures. Due to high and increasing demands on weight and loads, seat manufacturers are testing and ensuring the service life of the plain bearings. Otherwise, a car seat that is difficult to adjust or squeaks will reduce the quality for the user.

igus self-lubricating bearings for seat height adjustment – save time and reduce weight

Many millions of seats are equipped with various bearing points within seat height adjustment every year. Therefore, the assembly times of the plain bearings used are particularly crucial – every second saved and reduced work step brings great productivity benefits.

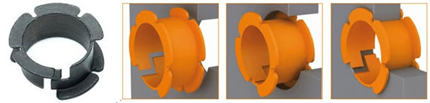

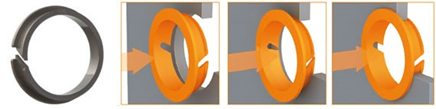

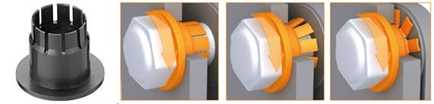

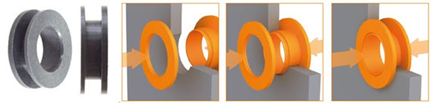

The innovative assembly concepts of igus plain bearings are particularly popular for hinge connections in, amongst other things the seat height adjustment. The igus clip bearings are easy to handle and increase efficiency. The flange processes and recalibration steps common to metallic plain bearings are eliminated. Further advantages are the weight (up to 5x lighter) and parts price reduction (up to 40%) compared to the metal version.

Igus clip on bearings for sheet metal seating solutions:

We would be pleased to present further advantages and possible applications of our tribologically optimized polymer plain bearings.

Annappa Venkatesh

Industry Manager Automotive & Robotics

Phone: 9342401293

email : avenkatesh@igus.net

To know more visit: https://www.igus.in/info/automotive-seat