How does the 7th axis extend the range of a welding cobot?

Shery George | 28 June 2022

how the application range of a cobot can be expanded with the use of drylin® ZLW, the so-called “7th axis”,is shown by the company RHEWUM® based in Remscheid. The company uses components and systems from Low Cost Automation when welding components with a collaborative robot. The use of low cost automation components helps the company to automate production cost-effectively.

Reading time: approx. 3 minutes

About the company RHEWUM®

For more than 70 years RHEWUM® has been developing and manufacturing screening machines for a range of dry and wet screening, as well as vibratory feeders. These include solutions for the screening of sugar, fertilisers, salts, plastic powders and granulates. “We manufacture individual customer solutions,” emphasises CEO Sigurd Schütz. “For each specific application, there is the most suitable screening machine.” All machines are precisely tailored to the respective requirement. “A particularly unique selling point is that we have been manufacturing the vibration motors required for this ourselves for a year and a half. As a screening machine manufacturer, we know best which motors fit exactly,” adds Marketing Manager Marcus Giesen.

How does the drylin® ZLW axis extend the range of a welding cobot?

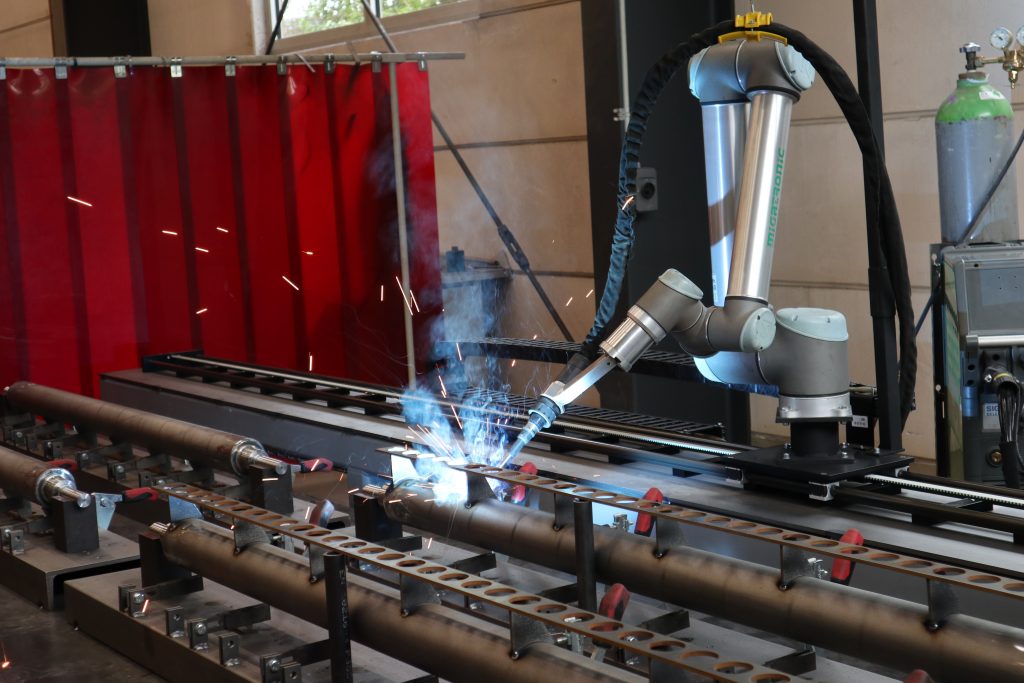

In the production hall of the company RHEWUM® a lightweight robot is used for the automated welding of components. A Universal Robot UR 10, which is equipped with low-cost automation solutions and energy chains from igus, has a payload of 10kg with a reach of 1,300mm. In order to make the robot’s workspace as flexible as possible, the collaborative robot travels on a 5.5m long seventh axis, the ZLW axis from igus® drylin®. The toothed belt axis ZLW-20 is designed for travel speeds of up to 300mm/s.

Low Cost Automation solutions for various applications under extreme conditions

The systems and components used for automated welding must be robust enough to withstand flying sparks and the associated higher temperatures.

The decisive factors for the choice of the seventh axis were, on the one hand, the travel distance to be achieved and, on the other hand, the price/performance ratio of the extension. For smaller companies, it is particularly important to make targeted investments to keep an eye on costs. And this is exactly what the low-cost automation solutions are designed for; from the gearbox to the articulated-arm robot to the seventh axis. The products are suitable for a wide range of applications, they are cost-effective and offer countless options for configuring the right customer-specific solution.

Matching the seventh axis, the machine builder uses an igus energy chain, the E4.1 for the safe supply and maintenance- free processes. The chain, which can be opened on both sides, offers a straight run due to the inner/outer link principle. It has a modular design and is quiet. The special sliding surfaces also ensure a long service life.

Easily master difficult tasks

What is harmless for the robot can involve great risk and effort for humans. In order to achieve a high reproducible quality of the weld seams, RHEWUM® uses the metal inert gas welding (MIG) process for welding. The components used in this environment must be designed to be tough enough for the welding sparks and the associated high temperatures. In everyday work, the automation solution means a significant reduction in workload.

Higher productivity, completely cost-efficient

The large heavy components can be placed with crane support. The worker then starts the respective welding programme and the robot undertakes the welding process. Originally, the component had to be rotated and turned several times for this process. The operator can now devote themselves to other value-adding tasks. The innovative production technology also provides an incentive for employees to take on this demanding task. New technologies often motivate the staff to familiarise themselves with the relevant activity and to use modern technology comfortably. Presently, swing axes are welded from several parts. The geometry of the axes varies from job to job. On average RHEWUM® produces 40 different screening machines per year.

“The robot comes at exactly the right time at this point,” says Sigurd Schütz. “Earlier, welding was done by hand. With the automated welding system we achieve a higher reproducibility of the high-quality weld seams. Secondly, our orders from various industries have increased since February 2021. This welcome this positive development.” The self-developed system is particularly suitable for recurring processes – also as parallel support for the welders. They can now take on other tasks that require even more human skills. “We are currently looking at what can be done with the plant,” says Schütz, commenting on the next steps. “The plan is to manufacture as many other components as possible here in the future. If that goes ahead, we’ll think about a second table in a similar form in the near future.

To know more, contact us at the details below:

Mr. Ragesh Kumar

Product Manager low cost automation

E-Mail: rkumar@igus.net

Mobile: +91 9606449648