How do I unreel cables correctly from the cable reel?

Shery George | 27 July 2022

At customers’ premises, I often observe how the electricians unwind cables from the cable reels or remove them from the cable ring in various ways during installation. You can go wrong here. Especially when the cable concerned is used for dynamic applications in energy chains, incorrect unreeling can have fatal consequences. To be honest, when I was in my apprenticeship as a power electronics engineer, I hadn’t given much thought to the correct unwinding of cables. This was partly due to a lack of expertise in cables, and partly due to the fact that both instructors and apprentices had never explained this. How do I unreel cables correctly?

What could happen?

If a cable is not properly unwound, it often results in “cable tangle” or the cable is stressed too much by torsion. It can even happen that the cable is bent during unwinding, because it gets tangled somewhere and is then subjected to too much tension. This can lead to damage to the stranding element as individual cores leave their original position in the stranding and are then subjected to greater compressive or tensile stress. All this can lead to premature failure due to corkscrew formation or core rupture when used in the energy chain. The machine shutdown is thus pre-programmed.

Unreeling cables correctly – What are the sources of error?

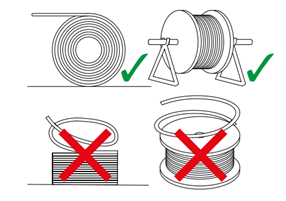

Let’s start with a cable ring. This is often packed in film and so it is a common practice to cut the film in the middle and remove the cable from the middle. In such a case, however, the cable is strongly twisted and a twist is drawn into the cable. In connection with the resulting tensile forces, the cable can also be bent in places. To avoid this, the cable should be completely removed from the film packaging and unwound straight from the outside.

Especially on construction sites, it often happens that cable reels lie on their side on the floor. So the cable can only be unreeled overhead. Often this happens because of missing unwinders or suitable cable racks. Without these aids, however, correct removal of the desired cable length is difficult.

In general, the cables must be laid without twist in the energy chain. Only then can we guarantee a long service life in moving applications. Therefore, care should always be taken when removing the cable from the cable ring or cable reel.

What if I do not have a cable unwinder?

Unreel cables correctly without a cable unwinder? With the chainflex® CASE, igus offers a clever solution. Here the shipping carton simultaneously becomes an unwinder. The chainflex® CASE is stackable and can be easily transported thanks to carrying handles. The cable reel in the box is mounted on a shaft, which allows easy unreeling. Depending on the type of cable, we can send up to 200m of cable cost-effectively by parcel service.

Want to know more about the chainflex® CASE? Here you will find more information.

Conclusion

Even the correct unreeling of a cable extends its service life permanently. Often initial damage is not visually apparent and only becomes noticeable after some time. The consequences are machine downtime, troubleshooting, loss of production and the resulting costs, which are quite avoidable.

Do you want to learn more about the correct handling of cables? igus® GmbH offers free on-site training for your employees in your company. If you are interested, our sales team will be happy to receive your call and provide you with further details about possible training courses at your company.