High performance polymer bearings from igus improve lifetime in heavy duty application.

Shery George | 13 July 2022

With the range of high performance, maintenance-free, lubrication-free, tribo-polymer plain bearings, igus can offer solution to heavy duty applications without need of greasing. These bearings offer high wear resistance at high loads.

Heavy duty applications for plain bearings generally seen in construction machines, agricultural equipment, hydraulic cylinders, mounting brackets etc have very challenging technical requirements considering harsh and dirty environments these machines are used in. Generally metallic bearings used in such applications are heavily greased. Adverse weather conditions can lead bearings to corrosion and premature failure in case of missing of lubrication or insufficient lubrication.

The motion plastic solution provider igus offers multiple polymer plain bearings as an alternative to frequently used lubricated metal bearings. The range of heavy-duty polymer bearing from igus includes:

1. Injection moulded polymer plain bearings from materials like Iglidur Q, Iglidur Q2, Iglidur Q2E, Iglidur Z, Iglidur G etc. These materials can offer long service life at high loads with extreme conditions. For example, a material like Iglidur Q2 offers a high wear resistance with a maximum permissible compressive strength of up to 130 Mpa.

2. Fibre wound polymer plain bearings from materials like Iglidur TX1 and Iglidur TX2. These bearings are made of high-strength filament fabric. The extremely strong filaments in its specially interwoven design ensures maximum wear resistance and enables a maximum permissible compressive strength of upto 400 MPa.

All iglidur plain bearings, including materials mentioned above are self-lubricating and operate in dry condition. This prevents dirt from adhering to the bearing points. It reduces maintenance and repair costs, as well as machine failures due to insufficient lubrication. With Iglidur bearings customer not only save on cost for lubrication oil (or grease) and maintenance time but also no lubricant is released in the environment. This accounts for increased sustainability requirements. A 16-tonne excavator needs between 50 to 60 litres of lubricants per year which finally ends up into the soil. With Iglidur bearings in use, contamination of soil can be reduced.

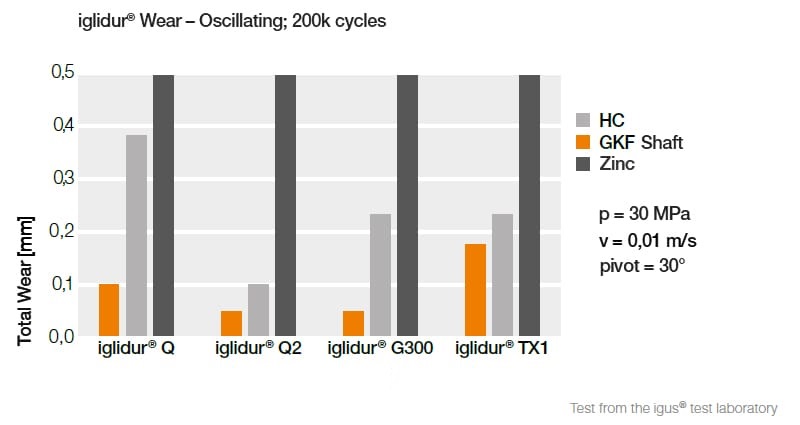

Iglidur polymer materials show high performance in heavy load conditions. They are extensively tested on the indoor and outdoor test rigs in the 3,800 square metre igus test laboratory. Pivot tests at 30 Mpa pressure and a pivoting angle of 30 degree were carried out for 200,000 cycles on multiple Iglidur materials with variety of shaft combinations. It shown wear results of as small as 0.05 mm in some of the heavy-duty materials in combination with GKF shafts. GKF treatment is a surface technology solution from igus, which protects shafts from both corrosion and wear. In this process, the shafts are gas nitrided and their tribological properties are optimised in additional processes.