Distribution Rules for Hydraulic hoses in the energy chain

Shery George | 19 October 2021

Machine tools very often have hydraulic hoses that are guided in e-chains – for clamping devices, coolant circuits and other applications. For hoses, as for electrical cables, there are several items to consider in the design and fitting of energy chains.

Rule 1 : Whether Crossbars every link or every second link ?

If a large number of hydraulic hoses are guided in an energy chain, an e-chain with crossbars every link is recommended. It distributes the pressure exerted by hydraulic hoses more evenly and minimizes the load on the crossbars.

Crossbars every second link

Crossbars every second link

Crossbars every link

Crossbars every link

Rule 2 : How much clearance must be plan for?

During interior separation planning, it is especially important to ensure that hydraulic hoses in particular need more space than electrical cables. For electrical cables, plan 10% of the cable diameter, but at least 1mm as free space on the left and right and 10% and at least 2mm over the electrical cable. For hydraulic hoses, it is at least 20%.

Rule 3: Hydraulic Hose Length consideration:

It is extremely important to adjust the lengths of hydraulic hoses within the energy chain or determine the correct lengths ahead of time. It is almost impossible to subsequently adjust hose length, especially when bulkhead fittings are used in front of and behind the e-chain. The length of hydraulic hoses can change when they are pressurized. All this must be considered when hose length is determined. It is best to determine the correct hose length when the machine is switched on and all hydraulic systems are at operating pressure.

Rule 4 : Strain relief options

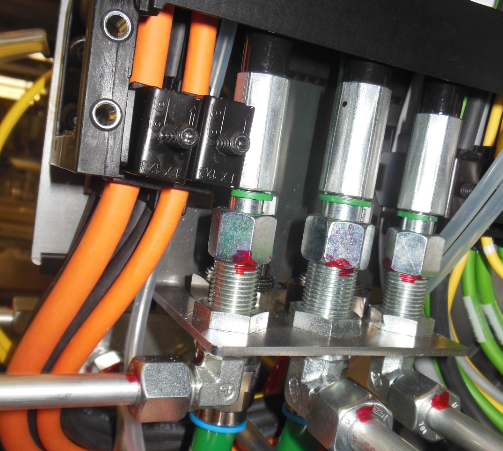

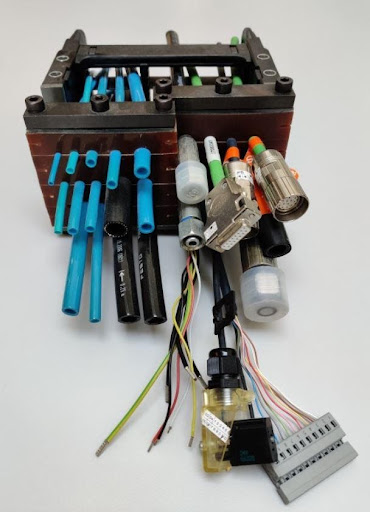

Hydraulic hoses should also be equipped with strain relief in front of and behind the energy chain. This relief is either a bulkhead fitting, CFX clamps, CFB strain relief connector systems or other suitable components.

CFB strain relief connector systems

Rule 5:Final check

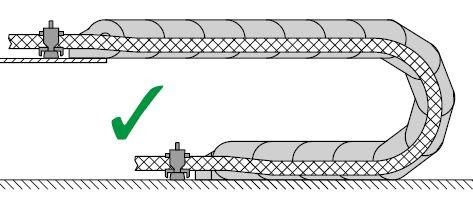

After cables and hoses are inserted and installed, the energy chain should be run to the two end positions several times to ensure that the cables and hoses have been fitted correctly. Check the correct hose length in the radius of the e-chain. The correct length is set when the hydraulic hoses have enough room in the direction of the crossbar (both inner and outer radius). Two hoses, one on top of the other, must also have the necessary space between them.

Check electrical cable length the same way.

Mr. Jai Vidyacharan

Industry Manager Machine Tools

| Mobile: | 9360051505 |

| E-Mail : | jVidyacharan@igus.net |

To Know More Visit : https://www.igus.in/info/industries-machine-tool-industry