Are igus products suitable for use with food contact?

Shery George | 11 January 2022

Our health is our most important possession and no components of the bearings or linear guide should ever harm it in anyway. Where there is possible contact with food, the requirements placed on each component are different from those in other cases. The linear guide system, i.e. guide rails, shafts, linear bearing housings, screws and so on, must be made of stainless steel. All other materials must be manufactured in accordance with EU or FDA regulations, whereby lubricated components must be specially encapsulated, and grease and oil can only be used in line with NSF guidelines*. The highest possible degree of corrosion-resistance, especially when chemicals are used in a cleaning process, is to be ensured.

In addition to the safety regulations, however, there is still the fact that it is a production industry. This means that production should be as efficient as possible and downtimes for cleaning purposes (also extremely efficient) must be kept short. Easy cleaning, legally compliant materials and extreme resistance to chemicals and corrosion are all features of igus linear stainless-steel guides made of 316 stainless steel (AISI 316Ti) in combination with plastic bearings. The absence of rolling elements and any form of lubrication enable very fast and uncomplicated high-pressure methods of cleaning.

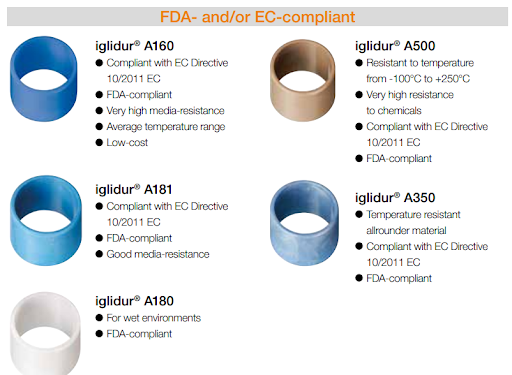

igus plain bearings comprises of FDA & EU compliant materials for the most varied operating conditions in terms of moisture & temperature & are dedicated to the food industry.

Suitable lubrication-free and easy-to-clean products as well as information on their use can be found below-

https://www.igus.in/info/linear-guides-linear-guides

https://www.igus.eu/info/iglidur-materials-for-contact-with-food

https://www.igus.in/info/industries-general-packaging

* The NSF is an American organisation that evaluates the suitability of all possible auxiliary and operating materials used in the vicinity of food and certifies suitable materials. In accordance with NSF, lubricants are divided into H classes: H1 can be used anywhere theoretically, whereas H2 must be secured by technical means in such a way that the lubricants cannot come into contact with the food.