Why do cables have different colours?

Vishaka Upreti | 29 March 2021

The market is full of countless cables. And they all have different colours. “A colourful bouquet full of safety” so to speak.

But why do cables have different colours anyway?

The cable structure and different colours

In view of the different colouring of cables, we look at the outer jacket and the individual cores inside the cable. In principle, a cable consists of several cores, unless it is a single core.

The colour of the outer jacket varies. And the colours of the individual core insulations are also different. There are specifications for this colouring, the so-called colour codes.

But why is this so?

The colour of the outer jacket

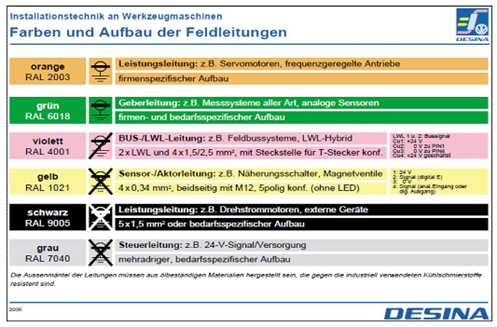

Our cables are also available in a variety of colours. The outer jackets are for example black, blue, green, orange or grey. We at igus follow international standards in terms of colouring. One of these is the so-called desina standard, which determines the colour of the outer jacket.

DESINA – The standard for general mechanical engineering

DESINA was brought to life by a consortium of well-known machine tool manufacturers. This standard stands for DEcentralised and Standardised INstAllation technology for machine tools and production systems. It describes the standardisation of the installation and makes the installer’s work easier.

This means the following for igus® chainflex® cables:

- If a cable is manufactured according to the DESINA standard, outer jacket colour must be chosen according to cable type (see graph).

- The outer jacket must be resistant to the coolants and lubricants used in industry

- The structure of the cable must be designed for use on machines in harsh environments

The colour of the core insulation

The colour of the cores of a cable can be chosen freely only to a limited extent. Here there are corresponding specifications of colour markings and DIN standards which must be observed. The respective colours also provide information about the functions of the cores.

The protective conductor (PE), for example, is always green-yellow. There is no exception for this colour coding.

Anyone who has ever connected a lamp themselves knows that coloured markings (e.g. black, brown, red or blue) are used for wiring in buildings. This is predetermined, simplifies installation and ensures greater safety.

Cables from igus are intended and designed for applications in moving machine parts. Power-carrying cores of larger cross-sections (from 0.5mm²) show a black colour here and are printed in white.

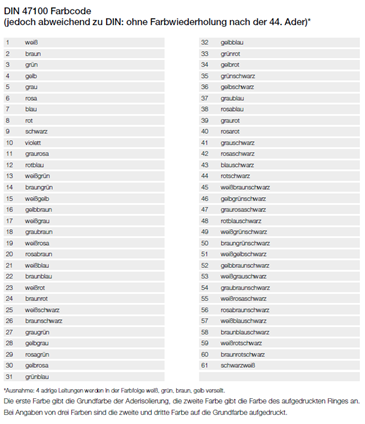

Data cables, on the other hand, are often marked according to DIN47100.

Since very small cross-sections (<0.5mm²) are used for these cable types, identification with digits would hardly be possible or would be difficult for the human eye to recognise.

Here is a list of the respective colours:

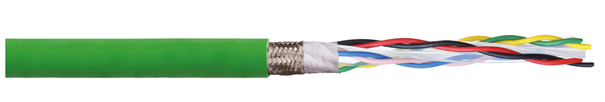

Bus and measuring system cables also have coloured core identification, but are based on the respective manufacturer system standards. These must be strictly observed in order to comply with the manufacturer’s documentation.

Why do cables have different colours?

The colours of the cables, both the outer jacket and the core insulation, are never purely random. Standards and regulations for labelling regulate the corresponding colours here. The situation is different for special types or special cables. Here the requirements of the respective target industries and/or customers can be taken into account.

Do you have questions about our range of cables? Or do you need information about our special cables or have specific colour requests? We would be happy to help.