Selection of the Suitable mounting bracket

Shery George | 19 October 2021

Almost all mounting brackets are available in two variants. The first pivoting, the second is locking.

At this point, many design engineers wonder when they should use the pivoting and when the locking version.

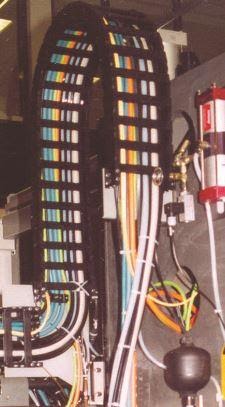

Pivoting Type

Pivoting Type

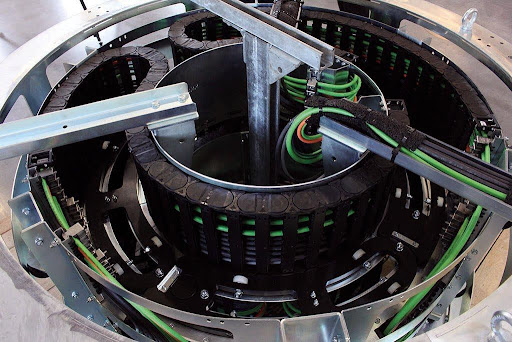

Locking Type

Locking Type

- Pivoting mounting brackets are standard for gliding and horizontally unsupported applications:

But why is that? The pivoting mounting bracket compensates for the sag resulting from the energy chain’s pretension. This makes it easy to install, and no other moments or forces are transmitted through the mounting bracket to the energy chain.

If the mounting bracket is not mounted exactly at radius height, the pivoting mounting bracket can compensate for smaller height differences.

2.Vertical standing installation position:

Pivoting mounting brackets can also be used in vertical standing installation positions. If they are, however, the energy chain must be supported on its outer radius. If such supports cannot be provided, Locking must be used.

3.Vertical hanging installation position:

Vertical hanging installation applications can almost always be planned with pivoting elements. If acceleration in the installation direction causes further forces and moments, the energy chain will swing back and forth. Support on the outer radius or use of Locking mounting brackets can prevent this swinging.

4.Rotary movement

In Rotary and winding movements Pivoting Mounting brackets are recommended for most applications.

Mr. Jai Vidyacharan

Industry Manager Machine Tools

| Mobile: | 9360051505 |

| E-Mail : | jVidyacharan@igus.net |

To Know More Visit : https://www.igus.in/info/industries-machine-tool-industry