Ready-to-install energy chain systems save harnessing time

Vishaka Upreti | 29 March 2021

Mechanical engineers have to adapt their machines time and time again to a new situation. Customer requirements, quality assurance specifications, and even market needs are changing constantly. This also requires an adaptability of manufacturing companies and their plant – on the one hand to meet the existing demand and on the other hand to remain competitive.

When is a good time to upgrade the machines to their state-of-the-art status? This question can be answered clearly with “never”. Both the changes to be made and the timing must be carefully planned. This is because adjustments are often associated with downtime due to the shutdown of the systems. They should be working again quickly. Furthermore, customers should not wait too long.

When does it make sense to carry out your own harnessing on site and when not?

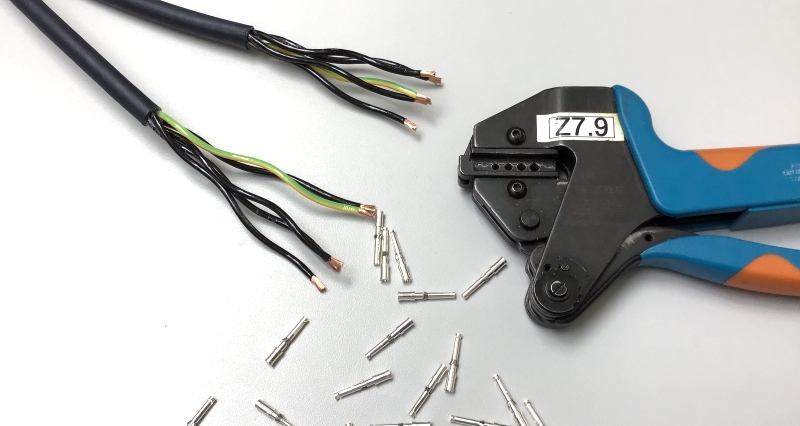

Situation: in a machine tool, an energy chain is used to optimally guarantee the energy supply in motion. This must be harnessed after delivery before it can be installed on the machine. This also includes the assignment of cables in the e-chain. If the cables are supplied as sold by the metre, they must now be connected to the appropriate plug-in connectors.

Before the energy supply system can be put into operation in the machine, a large number of components must first be procured, processed and adapted to one another. The harnessing not only takes a lot of time and effort, but also requires appropriate tools as well as technical and electro-technical knowledge.

It also goes faster

In such a complex case, a fully harnessed energy chain provides a remedy. Ready-to-connect cables are already integrated in it. igus manufactures ready-to-install energy supply systems, readychain systems. These are adapted to the individual requirements and environmental conditions. The main advantage for the customer is that the entire system comes from a single source and they do not have to worry about ordering and harnessing the components. The ready-to-install systems can save up to 95% harnessing time. This time can be used by the customer in the manufacturing plant instead.

Another point in favour of using readychain is that there is no need for specific knowledge on the subject of energy supply systems. After all, designing and implementing energy supply systems for dynamic applications is anything but trivial. Often there are small structural hurdles or practical obstacles that make it difficult to bring together cable and energy supply at the interface. If the installation takes longer or there are errors during commissioning, this can immediately have a negative impact on the overall budget.

With readychain, immediately functional units of cables and connectors can be installed on a system. And fast, because a “talking” label makes installation on the machine an intuitive action. This is where electricians and mechanics benefit, because someone without specialist knowledge can also make the connection.

The situation is completely different with self-constructed energy supply systems, where something can quickly go wrong. The most important factor in plant construction today is time. And the installation of cables in energy chains can cost a lot. The harnessing is just a set screw with which igus solves these problems.

If companies cannot carry out the installation of a ready-made chain on their system themselves for capacity reasons, they can fall back on the installation service provided by igus. The use of experienced assembly experts ensures timely and correct installation. Find more information on the topic of fully harnessed energy chains in the readychain overview or ask for an individual consultation here.