Polymer lead screw nuts and the influence of temperature

Vishaka Upreti | 8 June 2021

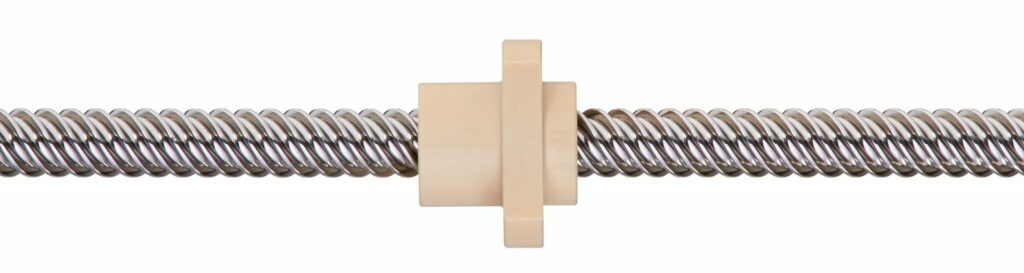

Lead screw drives are used in machines in a wide variety of industries. The demands on the lead screw drives therefore differ: high and low speeds and loads as well as wide temperature ranges or a continuous temperature of around 200°C. Even in these situations, lead screw nuts and lead screws have to work reliably. A distinction is made between the following lead screw drives: lubricated ball screw drives, dry running polymer lead screw drives and lubricated metal lead screw drives. From now on, we will focus on dry-running plastic lead screw nuts made of iglidur® materials.

A short digression: what are plastics in general?

Plastics are very long chains consisting of smaller parts (= monomers). There are basically three methods for creating a plastic from a variety of polymers: polymerisation, polyaddiction and polycondensation.

Here, the monomers themselves can be linear or branched molecules, so that the individual structural parts in a polymer can be cross-linked or non-cross-linked. Depending on the degree of branching of the polymer, you differentiate between thermoplastics and Duroplasts. However, there is a further degree of branching between the two mentioned. It shows only few cross-links, and such polymers are referred to as elastomers. The structure of the polymer thus has a significant effect on the temperature behaviour of the plastic.

Therefore, selecting the right material for the lead screw nut plays an important role. Short-term temperature differences, such as those caused by intensive cleaning with superheated steam, should also be taken into account when selecting materials.

That way, even small differences in temperature can result in noticeable changes regarding the mechanical specifications. Just as with other material classes, solid substances can be divided into ones that become malleable during heating and ones that don’t. Usually, this depends on the connection of the individual atoms or atom groups (primary bond) and the “linking” of individual polymer chains to a so-called macromolecule. When the material is heated, secondary bonds can be overcome, making it malleable. Primary bonds, however, can only be irreversibly destroyed when heated; in this case, the material would disintegrate.

And what exactly are thermoplastics?

Thermoplastics are polymers consisting of long linear or slightly branched polymer chains. The individual polymer chains are “linked” by means of Van der Waals forces or hydrogen bridges. These can become malleable when energy is supplied, usually in the form of heat or friction (overcoming of secondary bonds). Consequently, they can be formed to the desired shape with different (primary) shaping methods. After the part has cooled down, it keeps its shape. Basically, this process is reversible.

How is the application temperature defined?

The minimum application temperature is the temperature below which the material is so rigid and hard that it becomes too brittle for standard applications. The maximum continuous application temperature is the temperature the material can endure for a longer period of time without the properties changing considerably.

The maximum, short-term application temperature is the temperature above which the material becomes so soft, that it can only withstand small external loads. “Short term” is defined as a period of a few minutes.

Up to which temperature can I use the igus® lead screw nut?

igus offers polymer lead screw nuts that also work with higher application temperatures. For example, lead screw nuts made of the high-performance polymer iglidur® J350 are suitable for long-term use at temperatures of up to +150°C.

However, lead screw nuts have to be usable not only at high, but also at low temperatures. By default, our dryspin lead screw nut materials are intended for applications in the lower temperature range down to -20°C. For applications in lower temperatures or at a large temperature range, a detailed analysis is necessary. Please feel free to contact us in these cases.

The dryspin lead screw technology offers lead screw nuts from six different standard materials. Every material is ideally suited for specific applications. Our lead screw nuts made of iglidur® J are all-rounders and work in almost every application. However, this material is also limited regarding the temperature of the application. For a better understanding, we have summarised the differences of the individual standard materials for lead screw nuts in a table:

| Unit | iglidur® J | iglidur® J350 | iglidur® R | iglidur® A180 | iglidur® E7 | iglidur® J200 | ||

|---|---|---|---|---|---|---|---|---|

| Max. long-term application temperature | [°C] | + 90 | +150 | + 90 | + 90 | + 70 | + 90 | |

| Max. short-term operating temperature | [°C] | + 120 | + 150 | + 90 | + 90 | + 70 | + 90 | |

| Min. operating temperature | [°C] | – 20 | – 20 | – 20 | – 20 | – 20 | – 20 |

Should your operating temperature be above these limits, please feel free to contact us. We will test your application for you.