Why are users switching to lubrication-free plain bearings in construction machinery?

Shery George | 13 July 2022

Metallic plain bearings must be lubricated in order to function as a system. Grease is a part of the bearing system. On the other hand, with self-lubricating bearings like iglidur® plain bearings the addition of grease is not necessary.

In the construction machinery industry, lubrication-free plain bearings have seen increasing use. Eliminating the need for additional lubrication has several advantages that are presented below.

Cost savings

Properly maintaining the bearing system in construction machinery means cost and effort. Machines are lubricated with a grease gun (manually) or with a central lubrication system. Many construction machines use a combination of the two. So, there are costs not only for maintenance-related work and lubrication, but for investment in a central lubrication system.

Susceptibility to errors

Around 35% – 50% of all bearing damage results from improper lubrication. Around 14%-18% of all bearing failures are due to a dirty bearing point. Assembly errors cause 16%-18% of failures, and about 10%-34% are from material fatigue. These numbers vary from source to source.

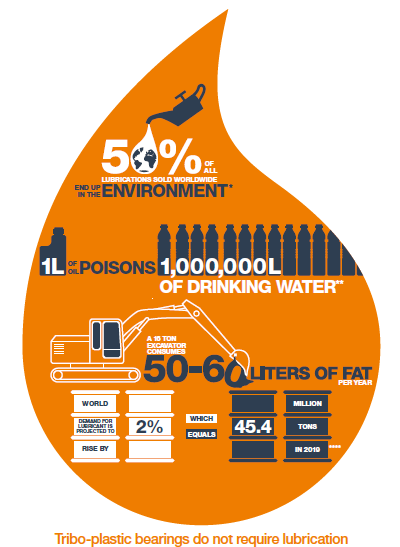

Environmental damage

Globally, 27 million tonnes of lubricating grease escape into the environment every year, which is why environmental protection regulations are becoming progressively more stringent. Many construction machines bearing points are protected from environmental influences and wear by so called “loss lubrication” systems, which continuously press lubricating grease from the machine’s interior to the outside. A 16-tonne excavator will thus eject 50-60 litres of grease per year that could potentially pollute the environment. One possible solution is environmentally friendly oils and greases, but they are very expensive. Because self-lubricating plain bearings require no additional greasing, they minimize external lubrication. A very small quantity of solid lubricant in plain bearings is enough to ensure bearing point function.

Eliminating the need for lubrication offers advantages likeReduced maintenance cost and effort, Elimination of cost of lubricants, No bearing damage from improper lubrication (this accounts for 50% of all bearing damage), No lubricants to pollute the environment (27 million tonnes each year…) and many more!

All these advantages encourage more and more manufacturers to look for bearing solutions that work with less grease/lubrication or none at all. Self-lubricating bearings like iglidur® plain bearings can offer a lubrication free bearing solution for construction machinery with high lifetimes at high loads.

To know more, contact us at the details below:

Mr. Nitin Prakash Vibhandik

Product Manager iglidur® Bearings

E-mail: nprakash@igus.net

Mobile : +91 7760368383