7 Tips for selecting the optimum conveyor rollers

Shery George | 27 April 2023

The following blog provides tips for selecting the right guide roller for each application.

Tip 1: Determine the load profile-

At the beginning of each selection process, the conveyor system design engineer should determine the requirements for the drive rollers and guide rollers. They will often notice that they can use more cost-effective guide rollers than the standard rollers, which are designed for high speeds and/ or loads. This reduces user costs without compromising roller performance properties or service life.

Product example: If the required load capacity is not too high, plastic guide rollers (made of PVC or carbon) or aluminum rollers from the igus® guide roller range can be used. They are cost-effective, and their modular construction allows adaptation to the individual application profile. In addition to cost, they have other advantages over standard rollers with steel jackets, such as the fact that they are corrosion-free and lightweight.

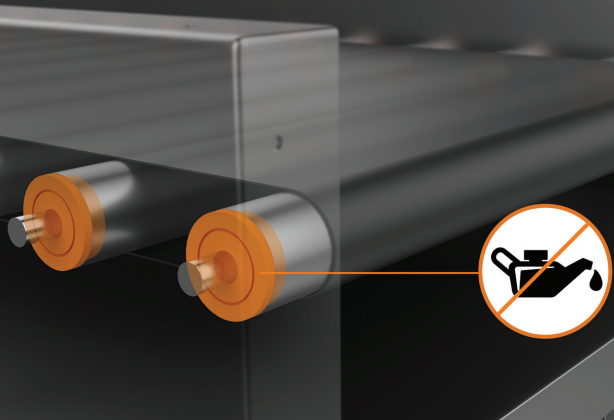

Tip 2: Determine whether you can remove the need for external lubrication-

Deep groove ball bearings for conventional guide rollers depend on continuous lubrication. In some cases, this can become a problem. These cases include hygiene-sensitive areas in food production, where lubrication must not contact the product, and harsh environments such as conveyor belts on agricultural machinery, where dust can mix with lubricant.

Product example: There are guide rollers with dry-running bearings that use xiros® deep groove ball bearings from igus®. A material combination of tribologically-optimized polymers and stainless steel balls ensures outstanding performance without external lubrication. Other advantages are the low breakaway torque and high resistance to chemicals and corrosion. These ball bearings are suitable for the low loads and speeds frequently encountered in material handling.

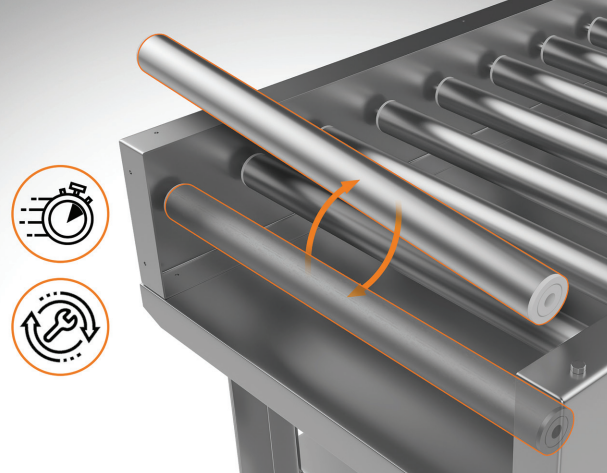

Tip 3: Ensure maintenance-friendliness-

During servicing, quick guide roller maintenance should be possible so that downtime is minimized.

Product example: igus® guide rollers are designed for easy installation. An essential design feature is modularity, so that individual components can be replaced quickly.

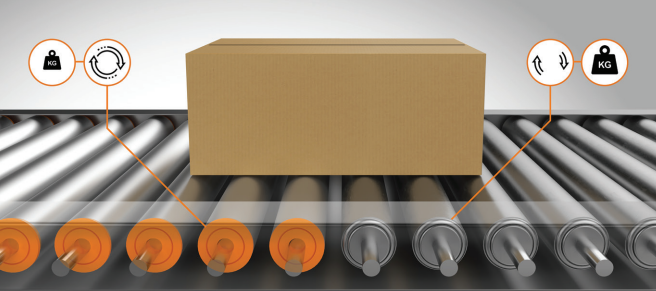

Tip 4: Keep an eye on energy efficiency-

Energy efficiency is an increasingly important factor in selecting driven rollers. It is greatly affected by interior friction (ball bearing, seal) and roller weight.

Product example: Guide rollers with aluminum or plastic jackets are much lighter than those with steel jackets. This means that when they are used as drive rollers, they require less energy and allow a quick start up with little energy consumption. This makes them especially well suited to dynamic applications with limited transported-goods weight.

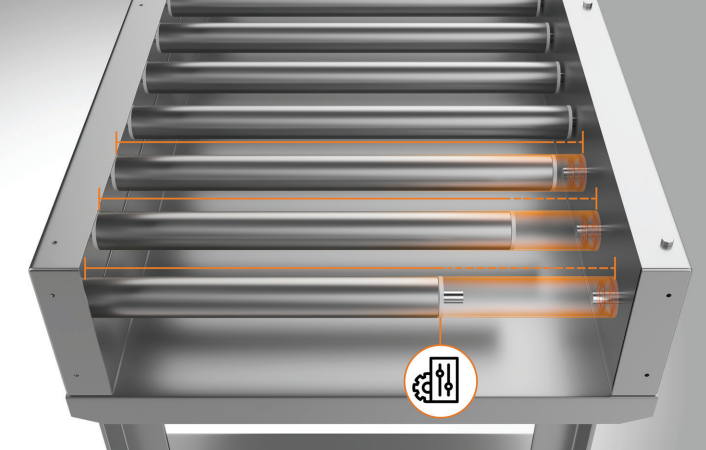

Tip 5: Optimize integration into the design-

The design engineer should always consider how the guide roller can be best integrated into the surrounding structure. Would special non-standard sizes be advantageous, for instance?

Product example: This question can be posed openly today because the igus® product range includes guide rollers that are 3D printed and customized to customer requirements. The combination of xiros® bearings and 3D printed housings and attachments allows guide rollers perfectly adapted to the overall design, rollers to be manufactured with special surface features, and for additional functions to be integrated. 3D printing also allows customer-specific pillow block bearings and fixed flange bearings to be manufactured in special sizes. xiros® guide rollers are also produced in customer-specific lengths.

Tip 6: Optimize existing conveyor systems-

The tips presented here do not only apply to new conveyor system design. Existing systems can be optimized in a targeted manner by means such as replacing guide rollers with rollers that are optimized for the application or replacing existing rolling bearings in rollers with special bearing inserts.

Product example: Maintenance-free igubal® bearing inserts can be installed in existing metal pillow block bearings and fixed flange bearings. They fit in existing bearing housings and have the potential to greatly increase bearing point service life because of their resistance to dirt, dust and corrosion. Practical test in comparison have returned results of up to eight times the service life of ball bearings, especially in dirty environments.

Tip 7: Look for holistic solutions-

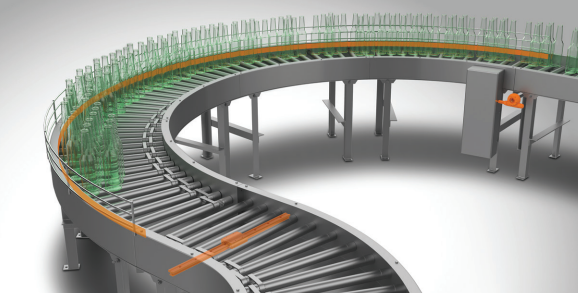

It is generally a good idea not only to focus on rollers, but to also consider the design in optimizing conveyor systems (whether existing or still to be designed). For example, the guide rollers should run as smoothly as possible, and to connect two conveyor belts, there is a knife edge roller with an especially small diameter that works particularly well when the transported goods are small.

Product example: In addition to guide rollers and knife edge rollers, the product range that igus® has developed for material handling applications now includes tribo-tape, a high performance polymer film that can be self-adhesive (optional) and has incorporated lubricant to improve the movement of transported-goods such as glass bottles around curves and through congested areas.

For more details about selection of igus Xiros rollers, pls. check below link-

https://xiros-guide-rollers-expert.igus.tools/dimension-and-load?l=en&c=IN

For more details, contact:

Mr. Tejash S Chavan

Industry Manager Packaging Industry

Mobile: +91 9375440499

E-Mail: tchavan@igus.net